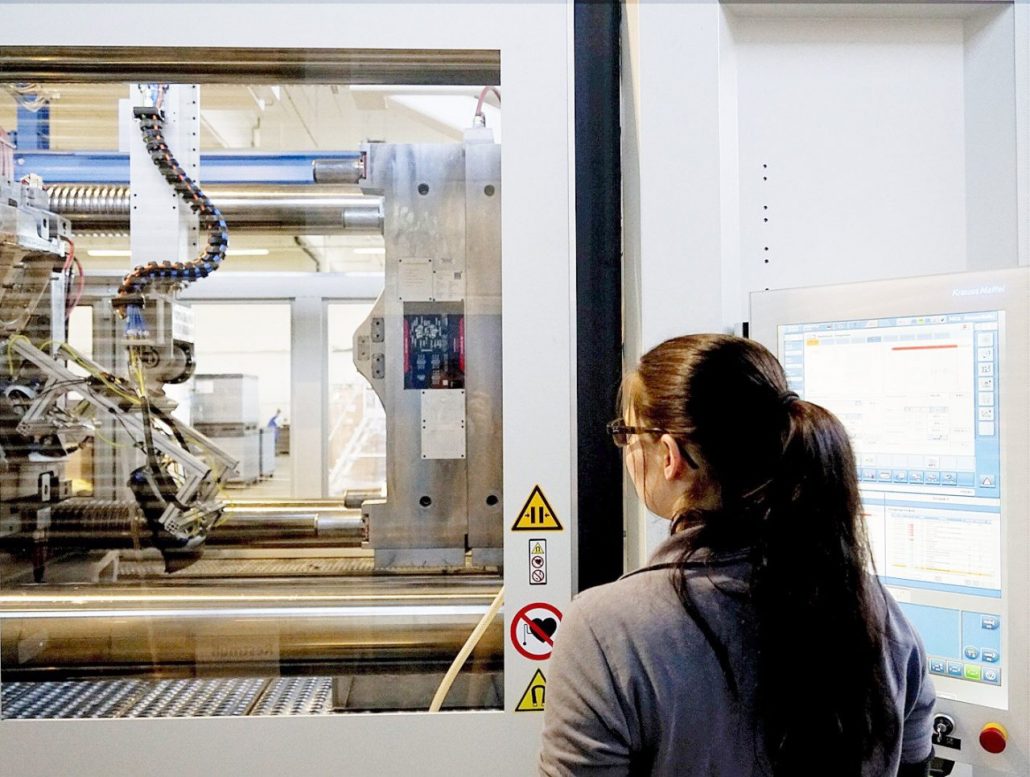

In order to complement the range of production technologies for our customers, Osbra has decided to build on its skills in the injection moulding field in-house. At the end of 2017, we will be installing an injection moulding machine with a force of 15000 kN, with the corresponding peripheral systems and automated extraction systems. The system is designed for components up to 3000 g in weight and tool dimensions of up to 1.40 m x 1.80 m and is suitable for radiator masks, radiator grilles, wheel expansions or spoilers. All conventional thermoplastics are suitable for processing.

If tool dimensions or capacities in-house are inadequate, we will arrange for appropriate components through an external, qualified partner. We are capable of meeting your requirements at all times.