As a system provider, we have mastered a multitude of technologies and skills. The name Osbra stands for innovative solutions in the plastic systems sector and high quality for completing small and medium size jobs. Our customers rightly expect technically reliable and cost-optimised products from us.

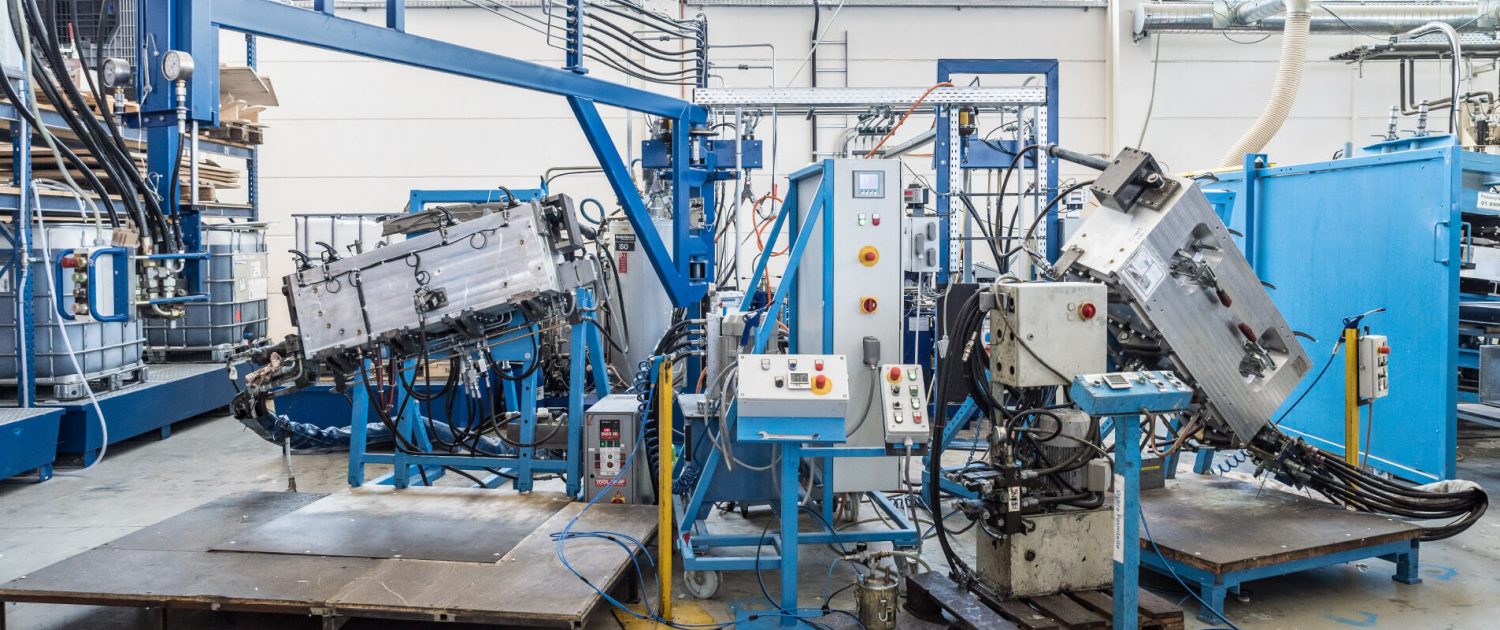

Our core skill lies in the use of highly diversified polyurethane foam methods. For our customers, Osbra offers a wide range of technologies for both hard and soft foam applications:

- R-RIM (Reinforced Reaction Injection Moulding) with glass and mineral fibre fillings

- S-RIM (Structural Reaction Injection Moulding) structured foam with fillers (e.g. glass matting with no restriction on length)

- Hard or integral foam

- PUR soft foam

- Film back foams

- Insert-/overmoulding

- InMouldCoating

- Lightweight PUR

Our system engineering includes toolholders with a force of up to 500 tonnes and modern piston injection systems that can be mixed with variable fibre contents.